LC5

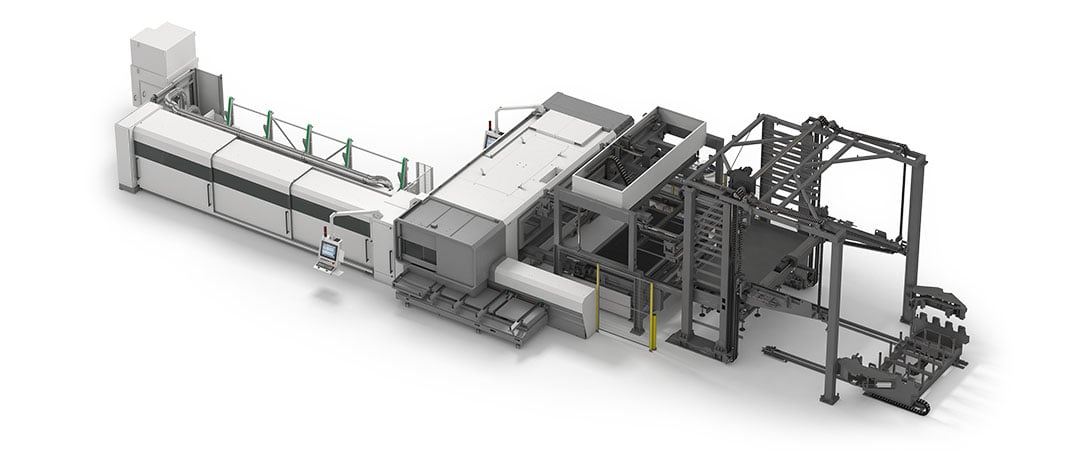

Two machines in one

One laser source and a single cutting head for two complementary processes, each with performance equal to

that of a dedicated system. LC5 is the answer when a small footprint is the key or if production volumes

do not justify two separate systems.

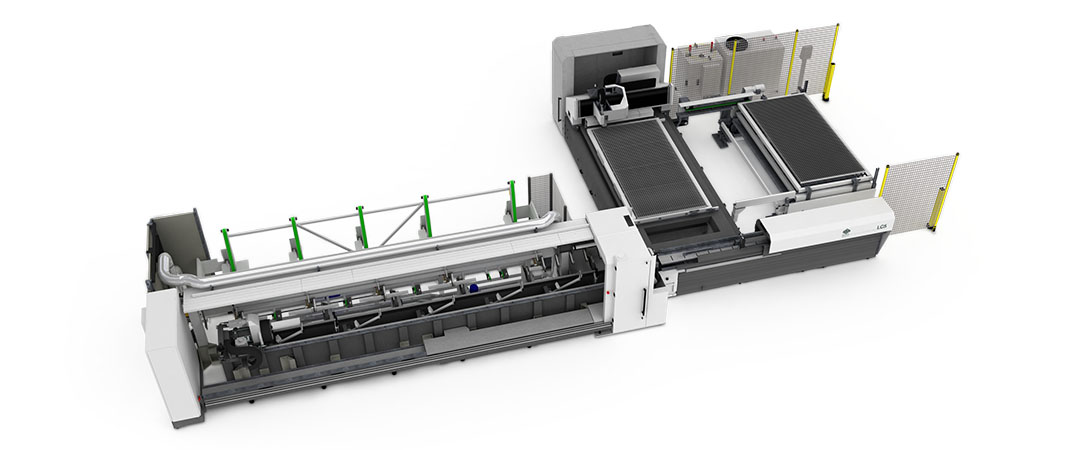

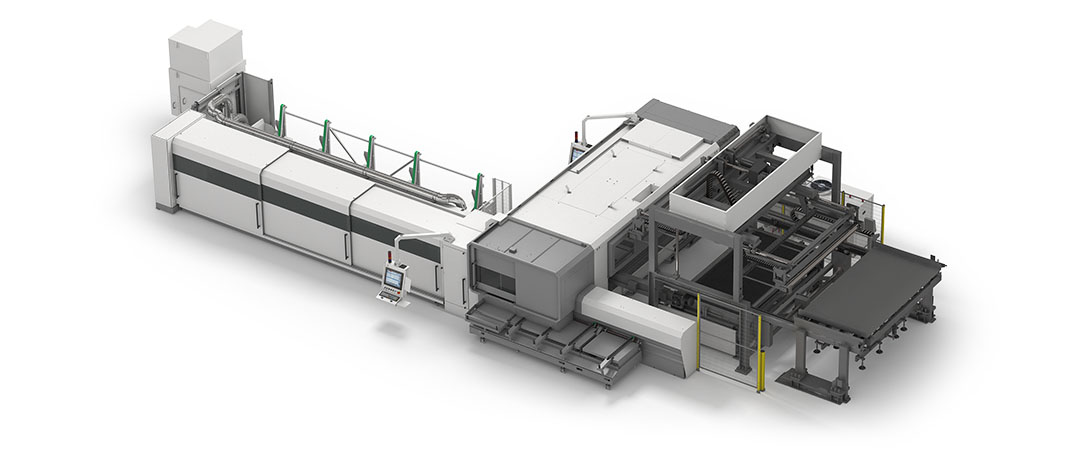

And as work volumes increase, you can add automated material handling systems, such as pallet

changers or storage towers.

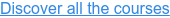

LC5

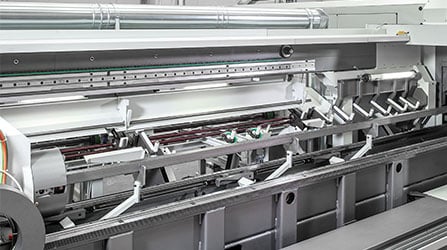

View of the two working zones for tubes and sheets

LC5

Sheet handling automation from pallet changer

LC5

Integration of the storage towers for automatic thickness and material changing

Ergonomic: made to be used

Large doors on the sheet side for convenient access to the entire pallet area and the same on the tube side to load a single bar on the fly and quickly adjust section changes.

Maximum control at all times thanks to access on sheet side and tube side.

Active Tools: productivity, safety, quality, automation and ease of use

Active Tools: productivity, safety, quality, automation and ease of use

Always perfect working parameters so you can get optimal results in less time, regardless of operator experience

This function is used to obtain high cutting quality faster even on the most critical cut features by recognizing the geometries and automatically optimizing cutting parameters.

This function assists the operator in centering the nozzle, simplifying and speeding up work considerably as a result.

This function allows you to utilize residual pieces of sheet metal in an easy, fast, and user-friendly method using an innovative viewing system.

You have the certainty of being able to work at Zero Risks and at the highest safety standards: LC5 is a CE marked, Class 1 system. Special glass and a completely closed cutting area protect you from the risks of laser radiation. An independent safety system on the loader allows you to introduce a new tube bundle without interrupting production.

The gain in speed, accuracy and efficiency is maximum.

LC5 Technical Information

Performance

Max. XY speed

5512 ipm (196 m/min)

Accuracy

± .002'' (0.05 mm)

Repeatability

± .001'' (0.03 mm)

Sheet working capacity

Materials

Mild steel, stainless steel, aluminum, copper, brass

Sheet work area

118'' x 59'' (3,000 x 1,500 mm)

157'' x 79'' (4,000 x 2,000 mm)

236'' x 79'' (6,000 x 2,000 mm)

Tube working capacity

Round tubes (Ø)

min .47'' (12 mm) – 4.72'' (max 120 mm)

Square tubes

min .47'' x .47'' (12 mm) – max 3.94'' x 3.94'' (100 mm)

Workable tube weight

max 9.1 lb/ft (13.5 kg)

Machinable bar length

min 126'' (3.2 m) – max 256'' / 335'' (6.5 / 8.5 m)

Unloading length

max 11.5' / 14.8' (3.5 / 4.5)

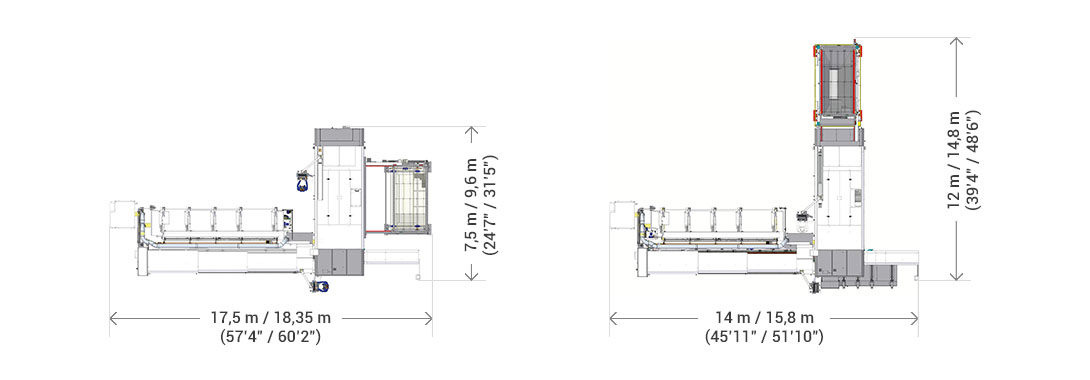

Dimensions

Transverse configuration dimensions (m)

Long side: 17.5 or 18.35 (57’4” or 60’2”)

Short side: 7.5 or 9.6 (24’7” or 31’5”)

Longitudinal configuration dimensions (m)

Long side: 14 or 15.8 (45’11” or 51’10”)

Short side: 12 or 14.8 (39’4” or 48’6”)

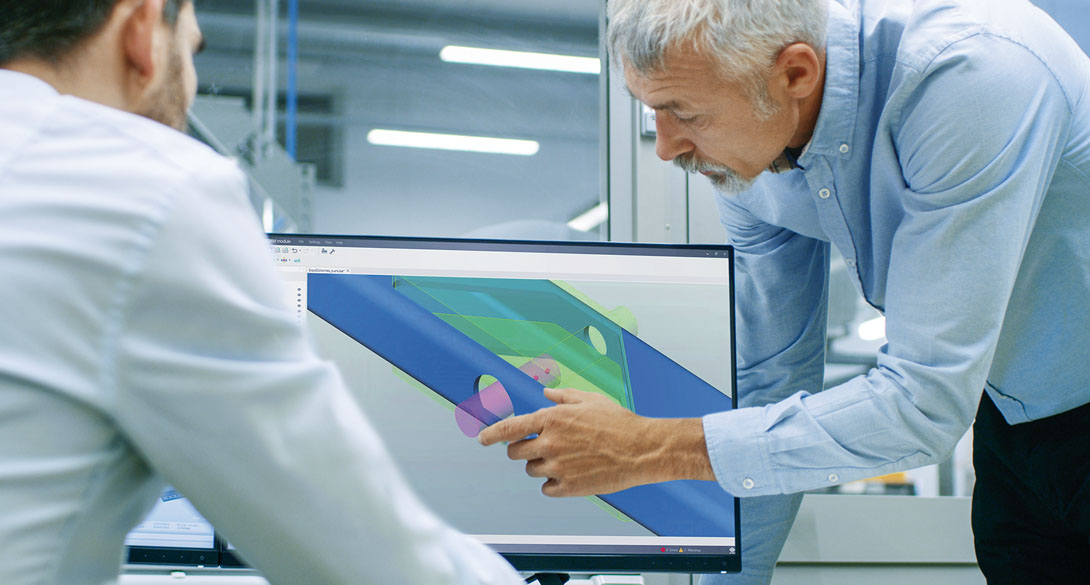

ArTube: from drawing to part in one click

Drawing a part, or an entire assembly, and transforming it into a machine program takes only a few seconds. You can import 3D models of parts drawn using other CAD programs and send all the information to the machine to start production on the fly.

With ArTube, you can use the full potential of the Lasertube from the word go,

without errors.