Add value to your production.

After cutting, the parts can be brush-deburred. You can certify the whole production with an additional contact-free measurement and quality analysis system installed on the line. The automatic washing system completes the process for perfect cleaning of the parts, inside and out. Finally, by adding a conveyor system, you can speed up part packing as well.

Have you ever considered laser cutting?

Have you ever considered laser cutting?

You can make perfectly clean parts in one single step on a laser system. The laser alone replaces cutting, measuring, brushing and washing with one-of-a-kind accuracy and repeatability and the possibility of adding other jobs to straight cuts.

Productivity can be surprising!

Compare the price cost of the two systems (traditional and laser) and then decide what one is best for you!

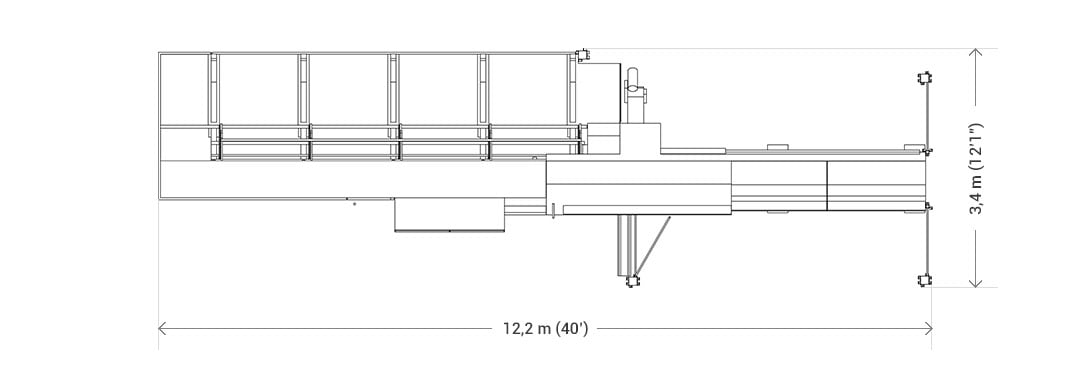

Technical specifications TS72

Workable diameter

Round tube cutting capabilities

min. 0.31'' (8 mm) - max 4.02'' (102 mm)

Square tube cutting capability

min. 0.39'' x 0.39'' (10 mm) - max. 3.15'' x 3.15'' (80 mm)

Bar cutting capability

max. 1.57'' (40 mm)

Minimum cutting length

0.79'' (20 mm)

Maximum cutting length

59'' (1500 mm) – 118'' (3000 mm) – 177'' (4500 mm)

Loading

Loading from bundle

fully automatic

Loading length

min. 78'' (2000 mm) – max. 255'' (6500 mm) / 334'' (8500 mm) / 492'' (12500 mm)

Unloading positions

3 + 1 (scrap)

Tools

Cutting blade diameter

from 7.87'' (200 mm) to 13.78'' (350 mm)

General

Total installed power (kW)

20

Basic machine weight

7496 lb (3400 kg)