- Home

- Machines

- Wire Benders

- E-FLEX

- Technical Information

Create with wire, simply

and productively.

Feeding.

Automatic coil feeding.

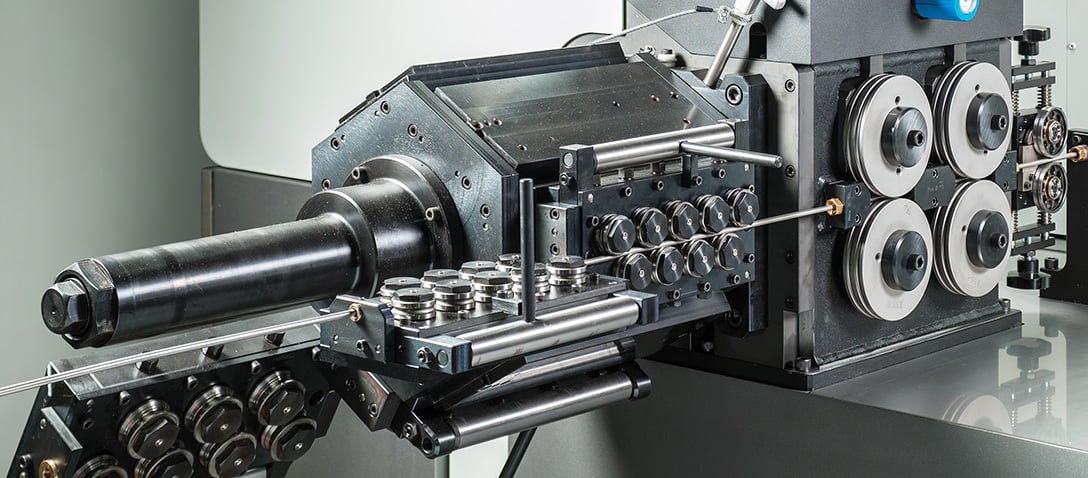

Straightening unit.

A battery of rollers fitted on multi-position revolvers straights the wire.

Cutting and chamfering.

The wire can be chamfered at the cut on both ends if required.

Bending.

The machine can apply various bending processes according to the type of bending tools used and the type of bends to be made.

Details that make the difference

Details that make the difference

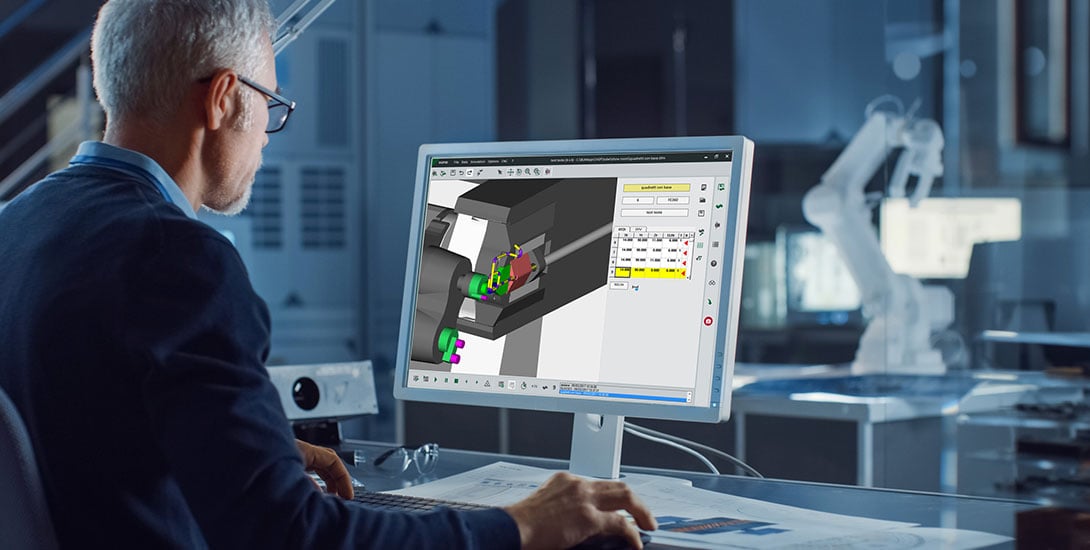

Program your geometry and produce your wire part, quickly and simply.

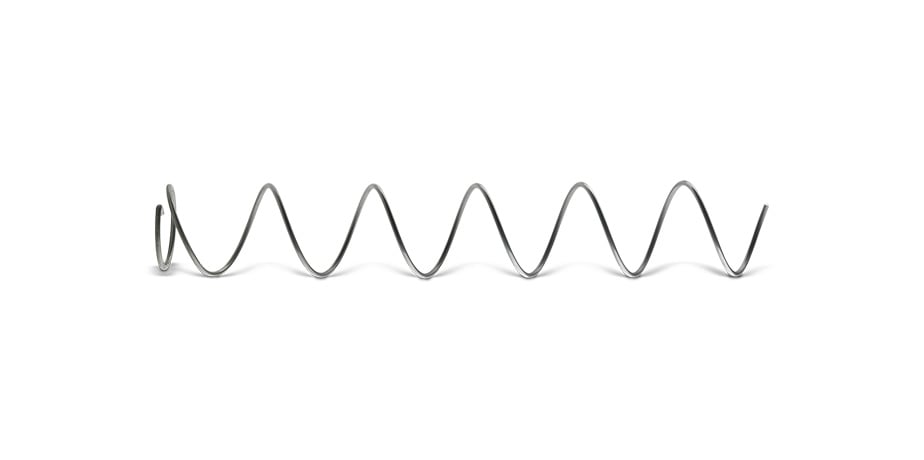

E-FLEX Applications.

Choose the safety

for your job

The pedal prevents dropping the parts at the end of the loading and unloading operations. The two-hand activation control prevents the operator from coming into contact with moving parts. To combine safety and efficiency, the laser scanner allows you to choose the size of the work area based on the size of the part you are working on. The machine is provided with the CE declaration of conformity and the user and maintenance manual.

Increase your production efficiency

Increase your production efficiency

Protube provides reliable quotes and allows you to identify the best production strategy for both single parts and entire production batches.

It also allows you to manage logistics, planning, monitoring, and productivity analysis with the capability to integrate to your ERP.

All the systems communicate with each other and simulate the production processes to simplify the operator's work and resolve any detected problems.

E-FLEX Technical specifications.

Bending capacity

Wire R = 130,000 psi (900 N/mm2)

Up to Ø .31'' (8 mm)

Wire R = 72,500 psi (500 N/mm2)

Up to Ø .39'' (10 mm)

Machine features

CNC axes

5

Bending angle

0.1° - 240°

Bending radius

.02'' (0.5 mm) - Infinite

Distance between bend die axis and rear dimension of head

24.6'' (600 mm)

Machine weight

5291 lb (2400 kg)

Coiler capacity

3,307 lb (1500 kg)

Power

Max. installed power

22 kW

Average drawn power

8 kW