- Home

- Machines

- 5-Axis Lasers

- LT-FREE

- Technical Information

Choose your configuration.

The dual fixed tables can be equipped with the most varied tooling to 5-Axis laser-cut any three-dimensional profile.

Dual fixed tables and single handling robot means being able to cut any three-dimensional workpiece, even bent and hydroformed tubes, in a single cycle without manual repositioning.

The two cutting zones, fed by two shuttle tables, allow loading and unloading operations and laser cutting of any three-dimensional workpiece.

The two cutting zones, fed by two shuttle tables, allow loading and unloading operations and 5-Axis laser cutting of any three-dimensional workpiece.

The handling robots, one in each area, mean being able to cut any three-dimensional workpiece, even bent and hydroformed tubes, in a single cycle with no need for manual repositioning.

The large rotary turn table allow loading and unloading operations and 5-Axis laser cutting of any three-dimensional workpiece.

Work non-stop during processing

Increase productivity with the dual cutting zones of the MID FLEX and HIGH FLEX configurations. With two shuttle tables and easy handling, the loading and unloading process is always optimal.

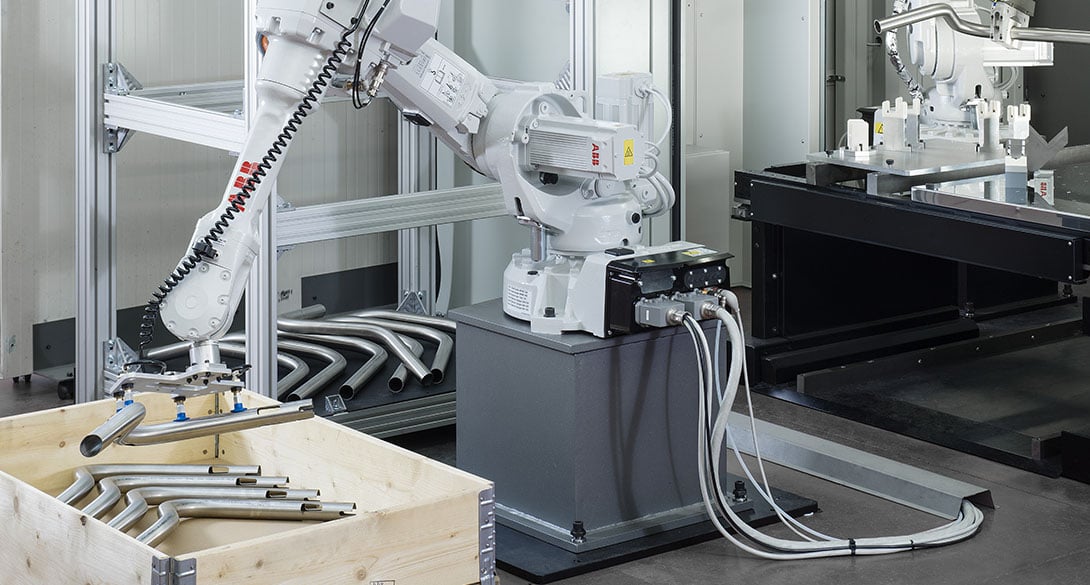

Superhuman precision and repeatability

Use the handling robot to maximize cutting accuracy and optimize cycle time.

The robot repositions the part in space, eliminating the need for manual repositioning and reconfiguration of the fixed jigs.

The cutting positions are repeatable and your result is always accurate and repeatable.

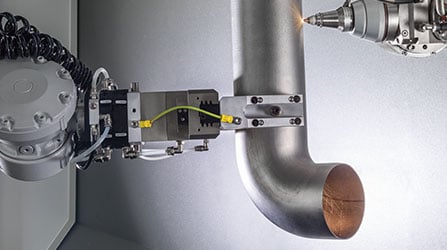

Narrow cutting head so you can get anywhere

Cut any geometry on any three-dimensional profile.

With the narrow design of the cutting head, the 5-axis CNC system coupled with the additional six degrees of freedom offered by the robot, allows you to reach anywhere on the workpiece.

Easier access, faster work

Simplify and speed up your work.

With the large front doors and two side doors, you have direct access to all internal machine components to carry out maintenance, checks, as well as loading and unloading of parts and scrap easily, quickly and safely.

Active Tools:

All the ways they can help you.

Active Tools:

All the ways they can help you.

Productivity, quality, simplicity, robustness.

With Active Tools you achieve the best laser cutting results on any three-dimensional part.

Manual or

robot feeding

Works 24/7 automatically with robot loading and unloading.

This solution allows you to integrate LT-FREE into larger production chains. When you want everything to be automated, LT-FREE will be the link in your work chain that you can no longer do without.

Choose the safety

for your job.

Work safely and confidently: The LT-FREE is a CE marked Class 1 system.

The enclosure is laser-safe and safety-interlocked. The two internal cameras allow you to monitor the process from the interface screen.

All-In-One

Manage scraps on bent tubes

All-In-One

Manage scraps on bent tubes

Increase your

production efficiency

Increase your

production efficiency

Protube provides reliable quotes and allows you to identify the best production strategy for both single parts and entire production batches.

It also allows you to manage logistics planning, monitoring and productivity analysis phases, with the possibility of integrating with your ERP.

.

All the systems communicate with each other and simulate the manufacturing process to support the solution of daily start-up and production changeover problems.

LT-FREE technical information

Cutting system

Fiber laser source

2 kW - 3 kW

Cutting head

3D

Number of axes of the head moving system

5

Accuracy

± .002" (0.05 mm)

Repeatability

± .002" (0.05 mm)

Cutting area and workpiece handling robot

Handling robot

ABB IRB 2600 20 Kg

HIGH FLEX and MID FLEX working tables

2, 120" x 39" (1500 mm x 1000 mm)

ENTRY LEVEL and ONE FLEX working table

1, 120" x 39" (3000 mm x 1000 mm)

PIECE VALUE working table

1 rotary table, 120" (3000 mm)

Enclosure

Class C1

General data

Installed power

60 – 66 kW

PC-based

SIEMENS

Operator interface

Unified BLM GROUP interface

Layout base LT-FREE

ENTRY LEVEL - ONE FLEX

Layout base LT-FREE

MID FLEX - HIGH FLEX

Layout base LT-FREE

PIECE VALUE

Don’t worry, we are there to advise you.