- Home

- Machines

- End Forming

- AST

- Technical Information

All the power you need.

You can choose the AST model according to the power and diameter you need.

AST80

120 kN thrust force, for tubes up to 4.0" (100 mm) diameter.

AST100

180 kN thrust force, for tubes up to 4.0" (100 mm) diameter.

AST122

Thrust force 220 kN, for tubes up to 4.0" (100 mm) diameter.

Unlimited job possibilities.

There are no limits to the variety of jobs you can perform.

All you need to do is equip the six workstations with fixed punches, revolving tools, and roller.

Equip it with everything you need.

Equip it with everything you need.

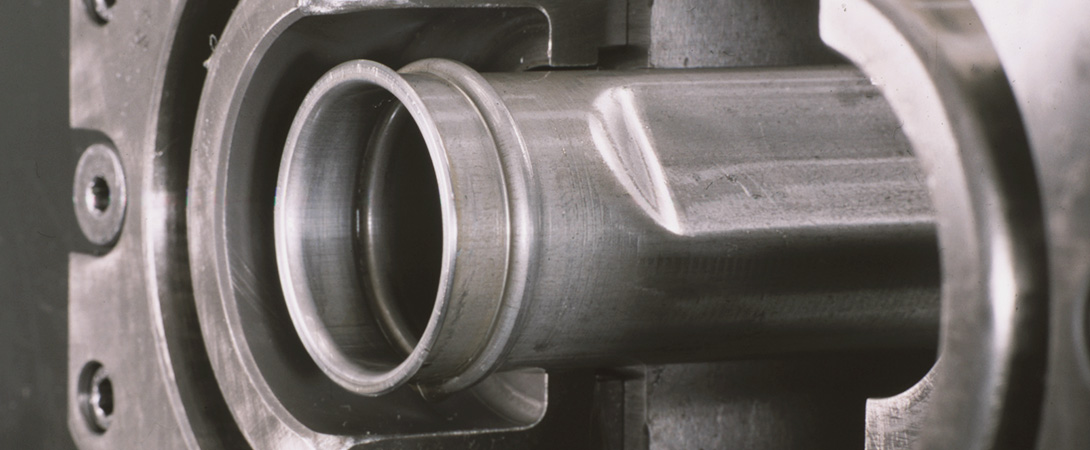

Quickly interchange punches

of any kind.

With the quick change system, switch out punches, clamps, and other components easily and efficiently. Your machine can be ready for new production in no time.

.

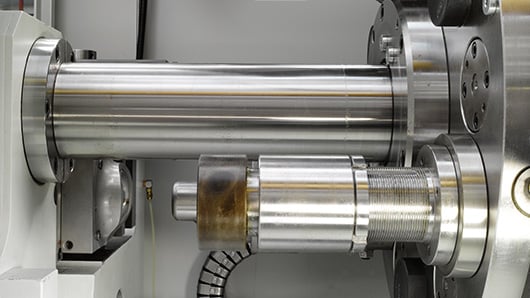

Roller: power and precision at

your disposal.

Nothing like the roller can allow you to create complex geometries in an extremely precise and repeatable way.

Trim everything in the machine faster.

By fitting an orbital cutting device, you can avoid part reworking which is typically required when pre-bent tube must be aligned to the forming operation.

Formed on both ends at once.

Reduce the cycle time.

With the automatic head and tail management, you get the finished part formed on both ends immediately.

AST Applications.

AST Applications.

Choose the safety

for your job.

The AST is a system with CE marking designed according to the strictest safety standards. The two-hand activation control prevents the operator from encountering the clamp when clamping the part.

The work area is completely closed. The safety door with sensors is equipped with a large Plexiglas window to control all stages of the work cycle. The clamp pre-closure system allows the workpiece to be always positioned safely.

Easy to learn.

Easy to use.

No experience needed - you can learn how to use the programming software in no time at all. Manage the two working axes with ease and go straight into production quickly and efficiently.

Choose the power supply and work 24/7.

Choose from a variety of automated material handling solutions:

simple automatic loaders to vibrators for loading bushings and/or nuts, up to complete robotic handling systems.

Create your production line.

Create your production line.

Get bent and end-formed part in one efficient work cycle. Eliminate secondary operations and create finished parts in one work cycle. Manage everything from a single control point.

Our tube end-forming and bending machines are designed to be integrated into complete production processes, allowing you to

optimize production, save time, and dedicate your staff to activities with the highest added value.

But integration is more than just that...

AST Technical Information.

AST80

AST100

AST122

Technical specifications

Maximum workable diameter

3.1'' (80 mm)

4.0'' (100 mm)

4.8'' (122 mm)

Maximum working stroke

7.1'' (180 mm)

7.1'' (180 mm)

7.1'' (180 mm)

Thrust

120 kN

180 kN

220 kN

Clamp closing time

220 kN

220 kN

330 kN

Weight of the machine

6614 lb (3000 kg)

6945 lb (3150 kg)

7297 lb (3310 kg)