- Home

- Machines

- Wire Benders

- DH4010VGP

- Technical Information

Two heads x two turrets

=

Feasibility2

Two heads x two turrets

=

Feasibility2

Multiply the benefits of a twin turret and expand your production capacity.

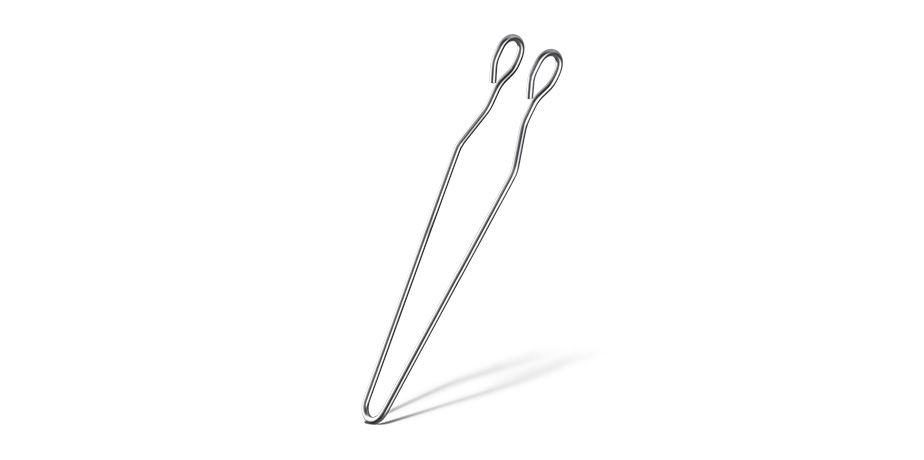

Double bending head

Reduce the cycle time by up to half on symmetrical parts and kick off new production on the machine quickly.

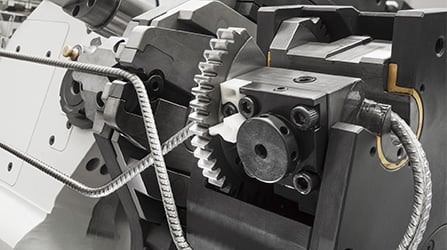

Twin bending turret

Combine multiple wire bending technologies and make up to three different bending radii on each part.

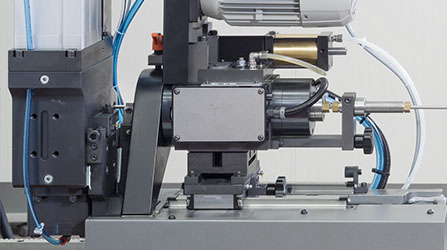

Independent end-machining carriage

Exact cutting and chamfering position coupled with optimized cycle time results from the cutting unit mounted on an independent carriage and directly controlled by VGP3D.

Retractable 3D handler

Achieve extremely short intermediate strokes by using the retractable 3D handler.

You can make the last bends by moving the bending heads to adjacent positions.

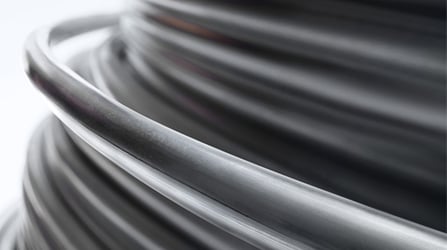

Fed from coil

Maximize your productivity by working non-stop 24/7.

Feeding from coil allows you to work fully-automatic.

Loading from bar

The bar feed configuration with manual or robotic feeding allows bending of a wide variety of material including flat, tube, bar, and wire-wound resistors.

Chamfer

The end finishing is flawless because it is done only after the piece is cut, on one or both ends of the wire.

Wire-wound resistors

Bend wire-wound resistors with extreme efficiency, precision, and reliability.

DH40 can be equipped with specific support platforms and 2D handlers.

The details make the difference

The details make the difference

Take advantage of its technological solutions for competitiveness2.

Work faster with the automatic ejection of the finished part and the control offered by the wire guide and the collet fitted on the head. Ideal tools to work both in manual and automatic 24/7.

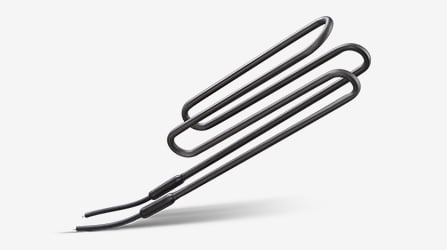

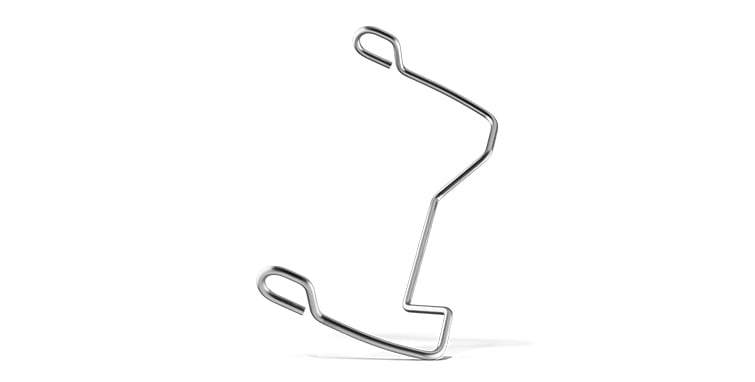

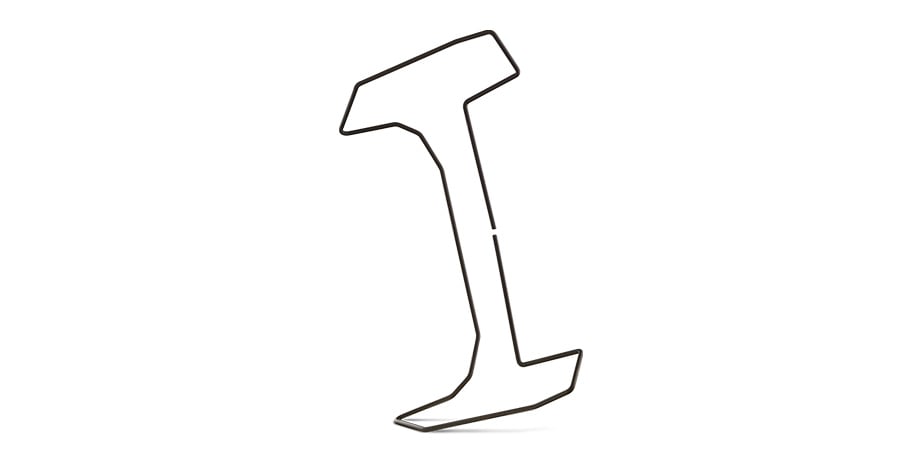

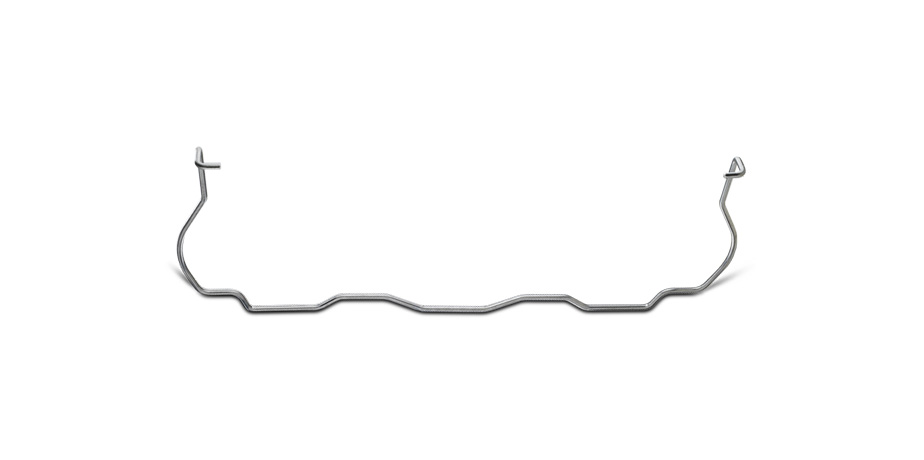

DH4010 Applications

Increase your

production efficiency

Increase your

production efficiency

Protube provides reliable quotes and allows you to identify the best production strategy for both single parts and entire production batches.

It also allows you to manage logistics, planning, monitoring, and productivity analysis with the capability to integrate to your ERP.

All the systems communicate with each other and simulate the production processes to simplify the operator's work and resolve any detected problems.

DH4010 Technical Information

DH4010

DH4012

Bending capacity

Wire R = 145000 psi (1000 N/mm2)

Up to Ø .31'' (8 mm)

Up to Ø .39'' (10 mm)

Wire R = 87000 psi (600 N/mm2)

Up to Ø .39'' (10 mm)

Up to Ø .47'' (12 mm)

Bending possibility

Flat rod, tubes, and wire-wound resistances

Machine features

CNC axes

9

Bending angle

0.1° - 240°

Bending radius

.02'' (0.5 mm) - Infinite

Working stroke

Up to 173'' (4400 mm)

Machine weight

8818 lb (4000 kg)

Coiler capacity

3307 lbs (1500 kg)

Max. installed power

Bar version

18 kW

Coil version

22 kW

Average drawn power

Bar version

6 kW

7 kW

Coil version

8 kW

9 kW

DH40

Bar loading

DH40

Coil loading