ALL-IN-ONE

Technologies integrated

into a single management suite

into a single management suite

Increase your competitiveness with technological integration

-

Eliminate semi-finished products to be handled and stored.

- Eliminate intermediate processes and secondary machining operations, working in line or in parallel.

- Eliminate errors resulting from the combined effect of several successive jobs.

- Eliminate inefficiencies, plan and monitor your process from a single point of management.

Tube bending machine and Lasertube together to always get the part right from the start

The laser-cut and bent tube right from the start. The smart Lasertubes and tube bending machines compensate for the deforming effects induced by bending offering you:

- Easy programming even without experience. No rejects, no need for trial and error.

- Precise and repeatable parts immediately.

- Efficiency in the production of large or small batches.

How the All-In-One works

How the All-In-One works

The result is a laser-cut and bent tube right from the start

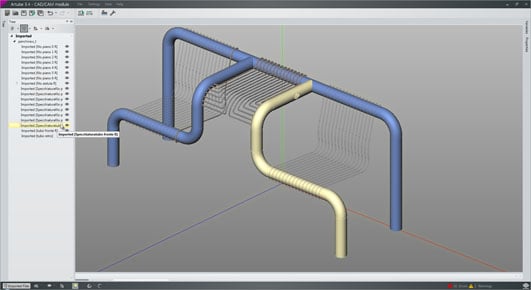

All from one single management point. ArTube

ArTube allows you to import curved tubes and get a single linear design for your Lasertube system.

The software estimates the deformations that the bending process will cause (springback and elongation), appropriately correcting the laser cutting path so your part is right from the start.

Always convenient integration! More on the multi-tube

Eliminate the multiplying effect of costs on multi-tube products. Exploit the flexibility of integrated systems to make more parts of an assembly in a single nesting.

The length of each part is already correct because All-In-One calculates the elongations of the next bending step.

Discover the machines you can integrate

Discover the machines you can integrate

Lasertube

Lasertube

LT5.10

The simplest way to enter the tube laser cutting world.

Tubes up to Ø 120 mm

2D cut

Fiber laser

LT7

The fully automatic solution that guarantees maximum productivity and fast changeover.

Tubes from Ø 12 mm to Ø 152.4 mm

3D cutting mode

Fiber laser

LT8.20

The solution with the widest working range in laser tube cutting.

Tubes up to Ø 240 mm

3D cutting mode

Fiber laser

LT FIBER EVO

The most productive solution for tubes of any section.

Tubes up to Ø 152.4 mm

2D cut

Fiber laser

LC5

Combined laser system for tube and sheet metal cutting.

Tubes up to Ø 120 mm

Sheets up to 6000 mm x 2000 mm

Fiber Laser

Tube bending machines

Tube bending machines

E-TURN

Ideal for complex parts without straight stretches between bends.

Tubes up to Ø 50.8 mm

Right-hand and left-hand in-process

All-electric technology.

ELECT

Ideal for large diameter tubes without straight stretches between bends.

Tubes up to Ø 150 mm

Right-hand or left-hand convertible

All-electric technology.

Coil-fed bending with mandrel: productivity and quality without compromise

With the production system fed from coil with mandrel, you can bend and shape the tube directly from coil achieving the required finish and the most stringent technological parameters (average radius, diameter, thickness, material).

Coil-fed manufacturing with mandrel offers you:

Bending of tubes fed from coil with average radii smaller than 1D.

Production flexibility because you program your part and start production just in time.

Maximum productivity with parallel machining, in continuous cycles, even 24/7.

Eliminate semi-finished products to be handled and stored.

Ability to use the machines independently.

From coil, bent with mandrel, and formed on both ends

Add a tube end-forming machine to form the tube on both ends. With BLM GROUP tube end-forming machines, you can carry out a wide variety of machining operations: tapering, widening, closing, single or double flaring, end-cutting, cutting, rolling and threading.

The simplicity of a single management point

The software corrects and calculates the elongation that the tube will undergo during the bending process to cut the part to the correct length. No manual set-up or adjustments are needed.

With VGPNext, you manage all the machines involved in the process from a single control point.

Coil-fed processing with mandrel

Coil-fed processing with mandrel

3-RUNNER

For making cut and end-formed tubes quickly from coil, the starting point for 24/7 processes.

Tubes up to Ø 27 mm

Stainless steel, copper, mild steel, aluminium

All-electric technology

SMART

High-production tube bending machine for complex shapes with small to medium diameter tubes.

Tubes up to Ø 28 mm

Right-hand and left-hand in-process

All-electric technology

Additional tube end-forming machines

Additional tube end-forming machines

AST8-VE

All-electric vertical tube end-forming machine.

Tubes up to 1.5” (40 mm)

7 workstations

Thrust up to 80 kN

E-FORM

Tube end-forming machine for tapering, widening, reducing, end-cutting, cutting, CNC rolling.

Tubes up to Ø 50 mm

Up to 100 kN of thrust

All-electric technology

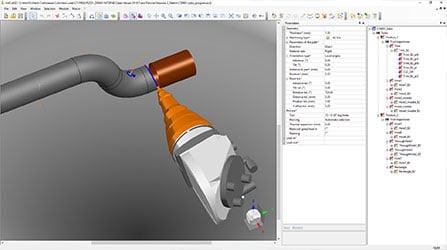

Tube bending and laser cutting integrated like never before

Go into production faster and safer with your 3D laser cutting system.

With ArtCut, you can manage the scrap on bent tubes without having to draw it in CAD, importing it directly from VGPNext or creating it with a few simple clicks.

Discover the machines with which to create your All-In-One process

Discover the machines with which to create your All-In-One process

3D laser cutting cells

3D laser cutting cells

LT-FREE

The most flexible and productive solution to enter the world of 3D laser cutting.

5-axis cutting head

Work area up to 3000 mm x 1000 mm

Fiber laser

LT360

The most cost-effective and versatile way to enter the 3D laser cutting world.

Cutting robot

Work area up to 1500 mm x 1000 mm

Fiber laser

Tube bending machines

Tube bending machines

E-TURN

Ideal for complex parts without straight stretches between bends.

Tubes up to Ø 50.8 mm

Right-hand and left-hand in-process

All-electric technology

ELECT

Ideal for large diameter tubes without straight stretches between bends.

Tubes up to Ø 150 mm

Right-hand or left-hand convertible

All-electric technology

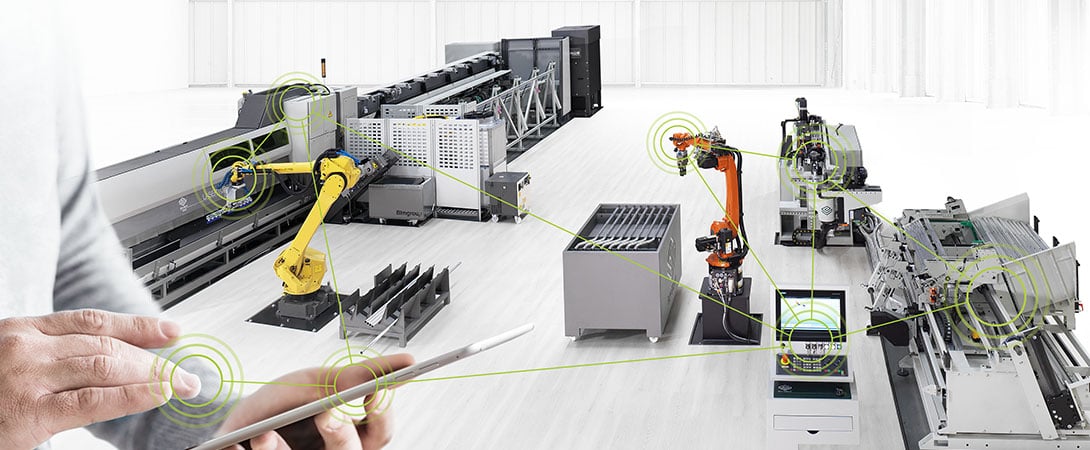

Workcells

Tube bending machines - Lasertubes - Tube end-forming machines - 3D laser cutting cells - Sawing machines

All our systems can be equipped with automatic loading or unloading systems, robot unloading, and conveyors and can be integrated into workcells or within broader production chains.

With our integrated solutions you can:

- Simplify logistics by eliminating intermediate steps and secondary machining operations

- Reduce the cycle time and cost per part.

- Control the entire system from a single management point.

Increase your production efficiency

Increase your production efficiency

ProTube provides reliable quotes and allows you to identify the best production strategy for both single parts and entire production batches.

It also allows you to manage logistics, planning, monitoring, and productivity analysis with the capability to integrate to your ERP.

All the systems communicate with each other and simulate the production processes to simplify the operator's work and resolve any detected problems.

Motorcycles

They have focused on quality and production flexibility to stay competitive in the global marketplace.

Find out how they did it with All-In-One.

Contractor

They eliminated scraps and trial and error and now they cut laser and bend right from the start.

Find out how they achieved this with All-In-One.

Research and development

Excellent for prototyping and solving laser cutting and bending issues that could arise upstream.

Find out how it did it with All-In-One.

Medical

DuPont Medical diversified their production capacity and expanded their market.

Find out how they did it with ELECT and LT5.10.

Motorcycle

It has combined flexibility, part quality and productivity to beat the competition from emerging countries.

Find out how they did it.

Accessories

They rapidly develop innovative solutions that are increasingly attractive and cost-efficient.

Find out how they do it with flexible, easy-to-use systems.