- Home

- Machines

- Tube Benders

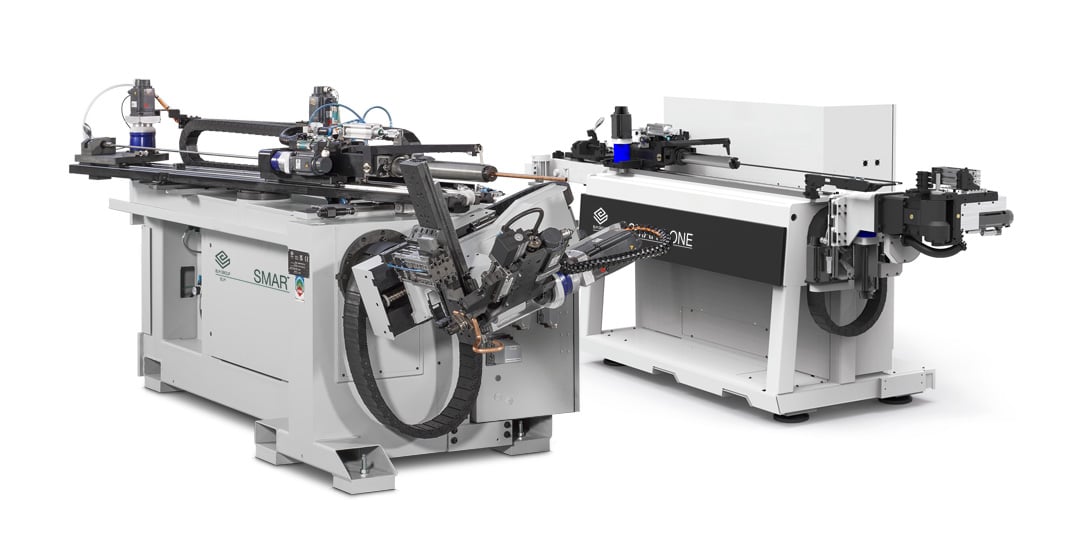

- SMART

- Technical Information

Simple and intelligent

No experience is needed to use SMART: All movements are managed by an electric axis. Set-up is automatic, and all position and power parameters are saved together with the part program.

Parts always right from the start

You can always count on repeatability and geometric precision of the bent part, regardless of shape and material.

SMART compensates for errors due to the springback of the part to always have the right parts right from the start, reducing rejects and set-up times to a minimum.

Designed for very tight bends

The machine adapts the working parameters to the material reactions such as elongation and springback, calibrating all the actions on the tube during the entire job to obtain curves with a centerline radius considerably lower than 1D.

Ideal when you have aesthetic needs and very limited spaces.

For bending special tubes

Flanges, fittings, flexible or corrugated parts.

With SMART you can bend any type of tube.

Ideal when upstream of the curvature there are processes such as end-forming or the fitting to other elements.

For bending busbar

Produce busbars for electrical power distribution.

With SMART, you can bend and twist the metal strips to obtain the common components of both the energy and e-mobility sectors.

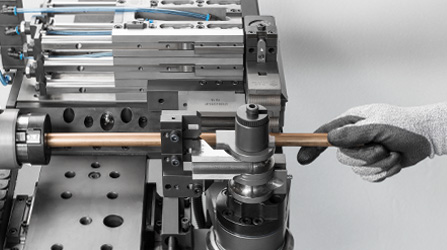

Simplicity of loading and unloading

The direct loading configuration is the ideal solution for those who prefer manual or robot loading.

You always have total repeatability of the parts produced, thanks to the stop reference

at loading, optical systems for hole search and automatic tube orientation.

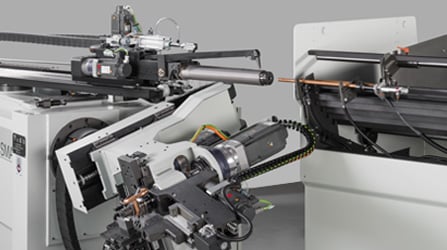

Overlapping times, maximum productivity

In integration with automatic loader, the Swinging Collect reduces cycle time by optimizing the loading phase.

The movement is fast and requires no adjustments.

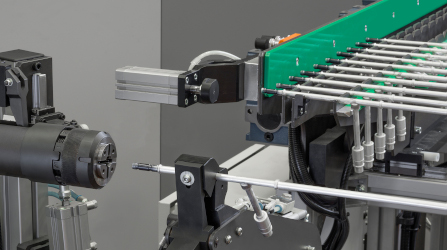

Thousands of feasible parts > thousands of solutions.

You can combine your SMART with a very wide variety of automatic feeding and loading systems: simple automatic loaders with high autonomy with the possibility of loading tubes with shaped ends, special loaders for pre-assembled tubes, with deformations at the ends or with flexible parts.

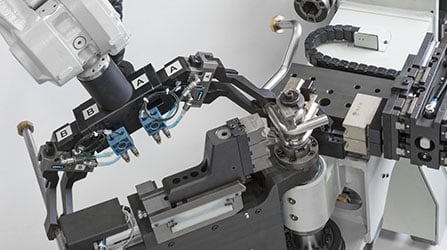

Choose robot integration

Whatever your production context, you know you can insert it easily.

Thanks to the integration with robots, SMART is perfect for working 24/7 in complex production cell.

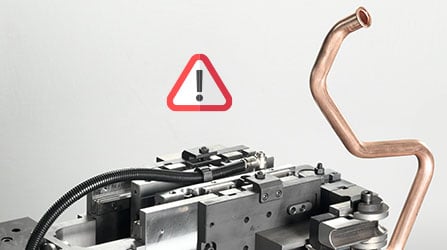

Always reliable

Even when there are no more conditions to continue, special sensors on the machine automatically block production.

Thus the processes, even if unattended, are always reliable and safe, with zero waste.

SMART Applications

Take no risks – choose your safety features

The pedal prevents dropping the parts at the end of the loading and unloading operations.

The two-hand activation control prevents the operator from coming into contact with moving parts.

To combine safety and efficiency, the laser scanner allows you to choose the size of the work area based on the size of the part you are working on.

The machine is provided with the CE declaration of conformity and the user and maintenance manual.

Curve from coil with core

Curve from coil with core

Connect 3-RUNNER with SMART and start a fully integrated process that starts from coil,

shape, cut and bend with core.

Reduce the cycle time and cost as you can perform multiple operations in parallel.

Eliminates semi-finished products to be handled and stored.

Curved with core and respects the most restrictive technological parameters of curvature

(average radius, diameter and thickness).

And don't stop there, discover our solutions for technological integration.

Increase your

production efficiency

Increase your

production efficiency

Protube provides reliable quotes and allows you to identify the best production strategy for both single parts and entire production batches.

It also allows you to manage logistics, planning, monitoring, and productivity analysis with the capability to integrate to your ERP.

All the systems communicate with each other and simulate the production processes to simplify the operator's work and resolve any detected problems.

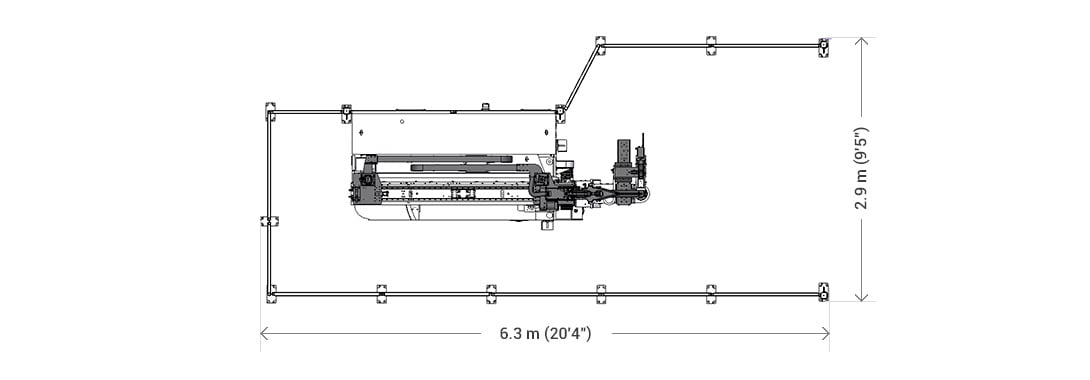

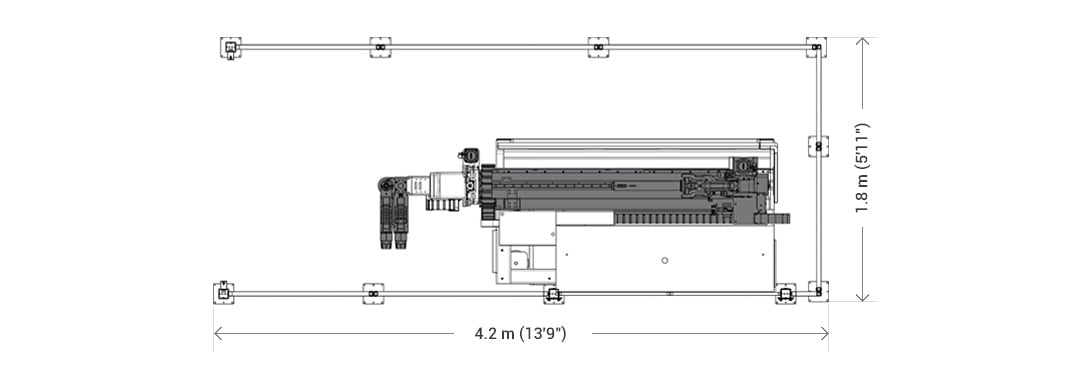

SMART Technical Information

SMART

Copper and Aluminium

Ø .98" x .06" (25 mm x 1.5 mm)

Ø .87" x .06" (22 mm x 1.5 mm)

AISI304 stainless steel

Ø .79" x .05" (20 mm x 1.2 mm)

Ø .55" x .04" (14 mm x 1 mm)

Copper and Aluminium

Ø 1.1" x .06" (28 mm x 1.5 mm)

AISI304 stainless steel

Ø .87" x .06" (22 mm x 1.5 mm)

Bending direction

In-process right-handed/left-handed

Right-handed or left-handed configurable

Axes

8 + 2 optionals

7 + 1 optional

X Accuracy

± .002" (0.05 mm)

± .002" (0.05 mm)

Y Accuracy

± 0.05°

± 0.05°

Z Accuracy

± 0.05°

± 0.05°

Clamp edge

50" (1,275 mm) (can be increased upon request)

61" (1,550 mm) (can be increased upon request)

Mandrel extractor

106" (2,700 mm) (can be increased upon request)

112" (2,840 mm) (can be increased upon request)

Max. installed power

13 kW

15 kW

Average drawn power

3.5 kW

3.5 kW

Noise level

65 dB(A)

65 dB(A)

Weight

4.189 lb (1,900 kg)

4.086 lb (1,400 kg)

SMART

SMART-ONE