- Home

- Machines

- End Forming

- 3-RUNNER

- Technical Information

Your process in just-in-time perspective.

Choose the configuration that best suits the processing you want to perform.

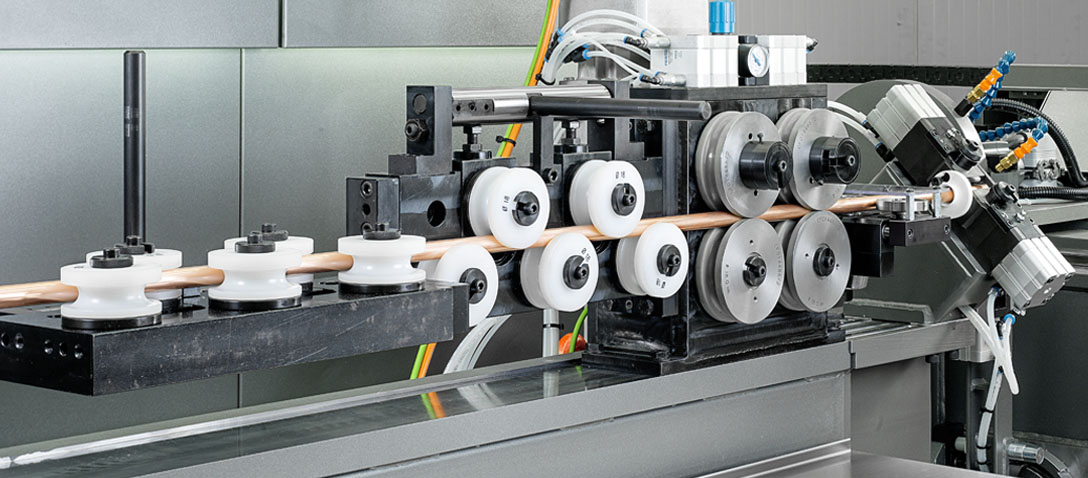

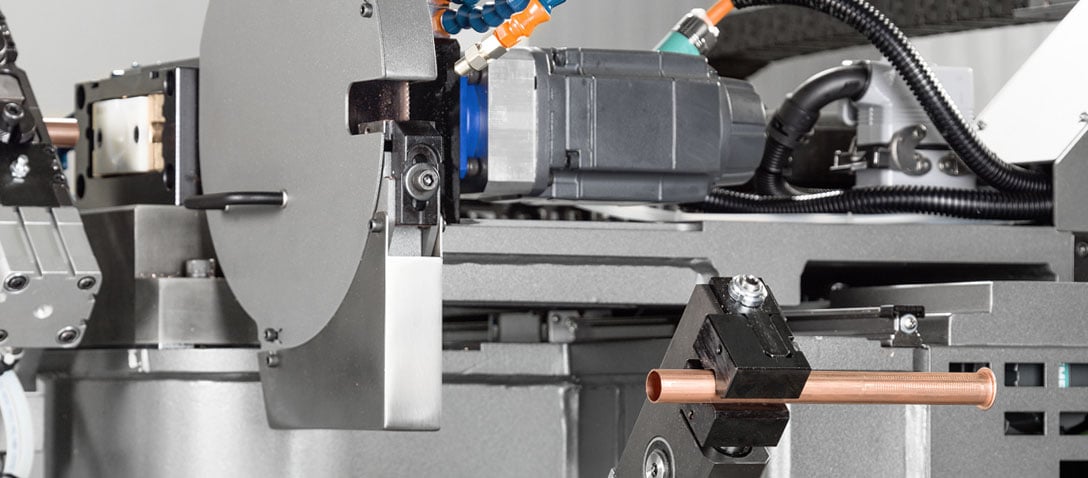

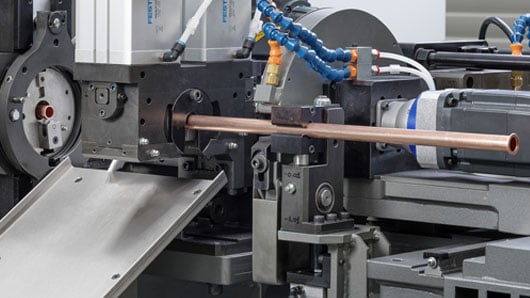

Feeding from motorized coil feeder

The tube is straightened out by a series of rollers

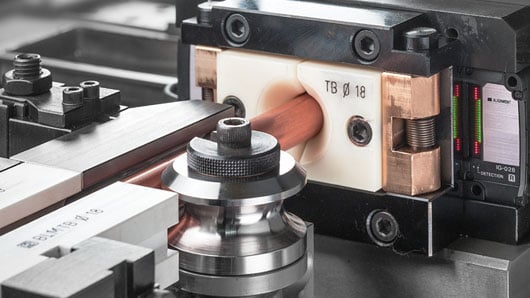

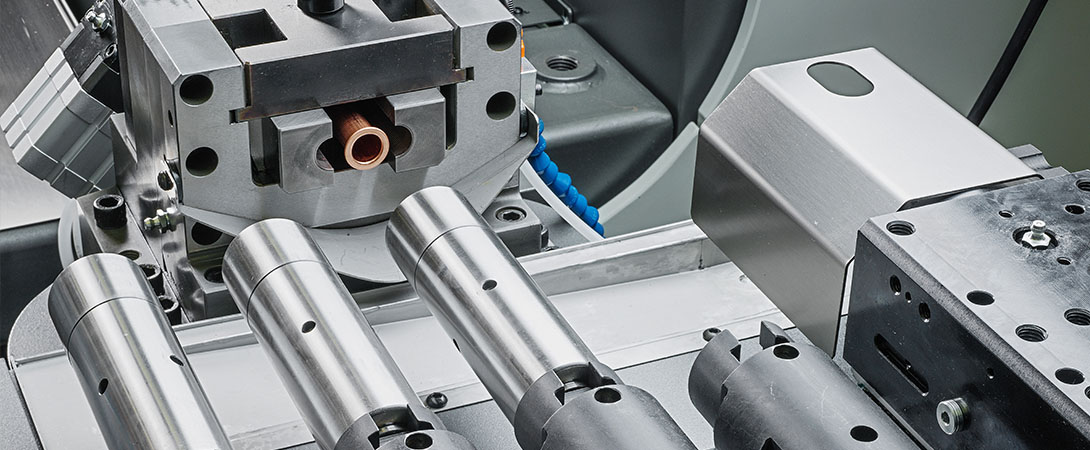

The end-forming module may be configured with up to six rams or four rams and one rotary rolling/finishing device

Cutting is performed using orbital scoring or saw cutting devices.

The automatic unloading device is fully-integrated into the work cycle and managed by the CNC

End-form the part the

way you want.

Configure the end-forming module with four fixed rams and a rotary finisher/rolling device or six fixed rams, and the integrated unloading system.

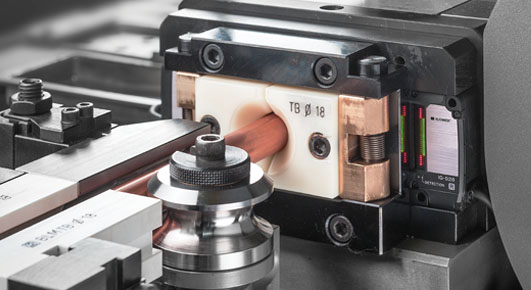

Exchange ram form tools quickly! The set-up is automatic and does not require manual adjustments.

The quick-change system is designed to be simple and allow you to change each ram form tool in a few seconds, eliminating any risk of positioning or clamping errors, even by inexperienced operators.

A device cut to your needs.

A device cut to your needs.

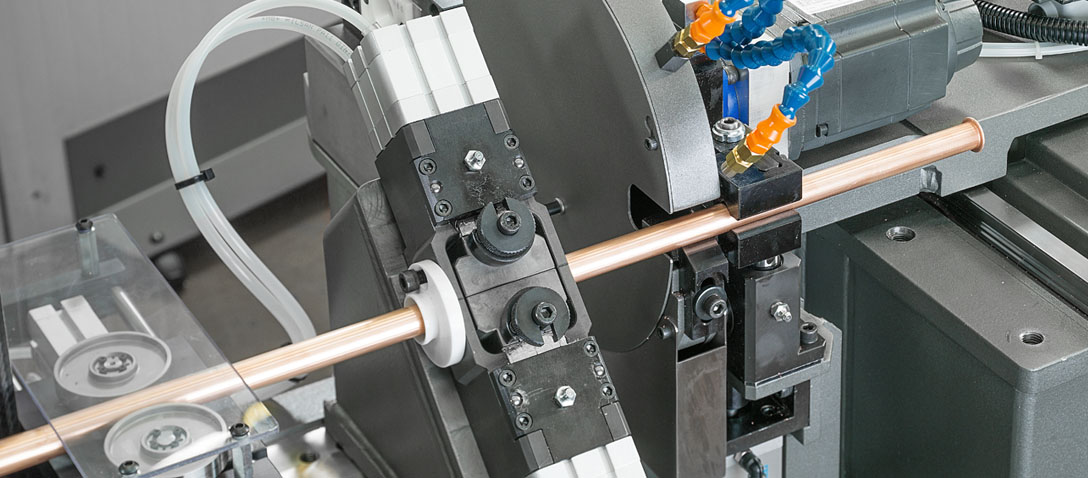

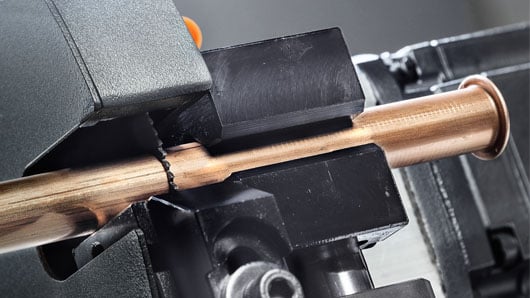

For clean, chip-free cutting.

Eliminate swarf and achieve the highest edge quality by using the orbital scoring device that can be integrated in the machine or in the final end-forming module.

Very fast, very versatile.

Maximize productivity with the saw cutting system fitted on the end-forming module and managed by a dedicated electric axis. .

Are you ready for a

new production?

Exchange ram form tools quickly! The quick-change system is designed to be simple and allow you to change each ram form tool in a few seconds, eliminating any risk of positioning or clamping errors, even by inexperienced operators.

The set-up is automatic and does not require manual adjustments.

Perfect repeatability and quality.

Have complete confidence in the quality of your batch using the dimensional geometry control in real-time and on each part.

3-RUNNER Applications.

3-RUNNER Applications.

Choose the safety

for your job.

3-RUNNER is CE certified and designed with safety features to

protect the operator during machine operation.

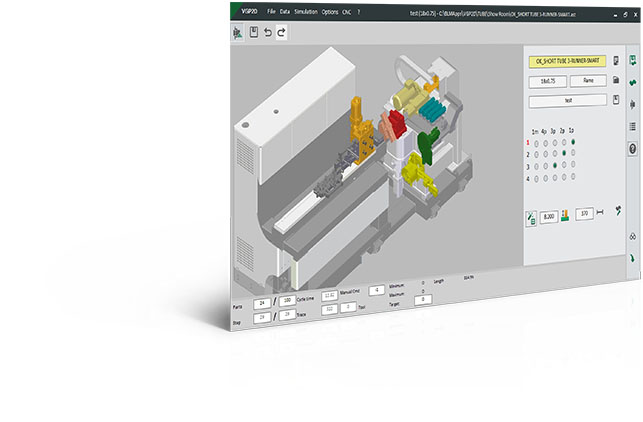

VGP2D:

learn and start immediately.

Program the work sequence simply and intuitively. Simply select the punch you want to use and VGP2 programming software will set the optimal parameters for you.

You decide where to start.

Choose the coil feeder that best suits your production or space requirements: vertical, horizontal or Jumbo.

The tube advancement and recovery is performed in-process and the motor is controlled in both directions.

The feeder may be used in idle mode by selecting the function on the VGP3D program which is fully integrated with the machine software.

Bend from coil with mandrel!

Bend from coil with mandrel!

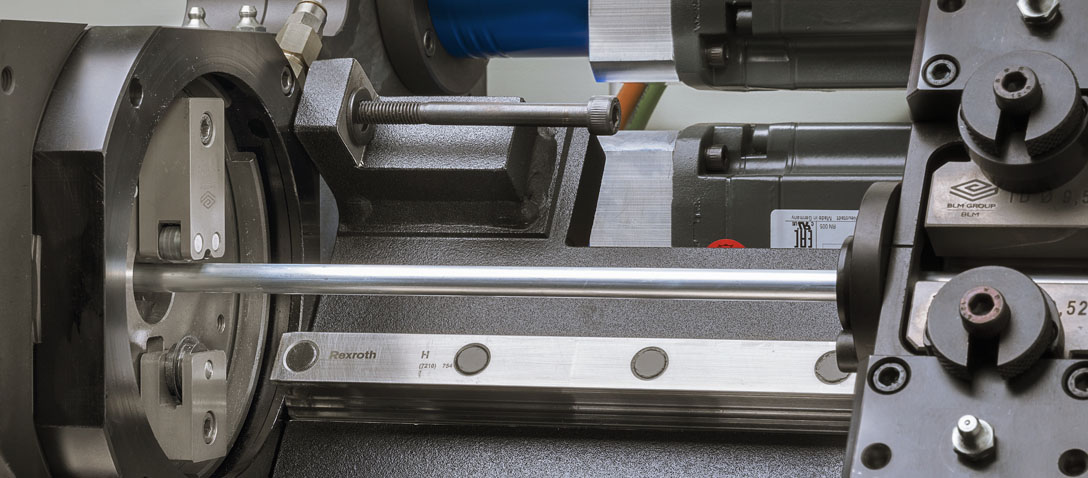

Connect the 3-RUNNER to the SMART and create a fully integrated process feed from a coil, end-form, cut and bend with mandrel.

Reduce the cycle time and the cost per part by performing several operations in parallel.

Eliminate semi-finished products to be handled and stored.

Bend with mandrel and comply with the strictest tolerances (average radius, diameter and thickness).

And it doesn't stop here. Discover our complete production solutions.

3-RUNNER Technical Information.

Maximum round tube bending capacity

Aluminum

1.13'' x 0.06'' (28.6 mm x 1.5 mm)

Copper

1.13'' x 0.06'' (28.6 mm x 1.5 mm)

Mild steel R = 52214 psi (360 N/mm²)

0.55'' x 0.04'' (14 x 1 mm)

Stainless steel

0.71'' x 0.04'' (18 mm x 1 mm)

Machine features

Axes

Up to 8

X Accuracy

± .002'' (0.05 mm)

Passage

1.18'' (30 mm)

Max. installed power

12 kW (16 kW with accessories)

Average drawn power

4 kW

Machine weight without end-forming module

3858 lb (1750 kg)

End-forming module weight

1,350 kg

Handling

Up to 9 axes all governed by CNC

3-RUNNER

Basic machine layout

3-RUNNER

Basic machine layout with

shaping module