Simplified production and production monitoring

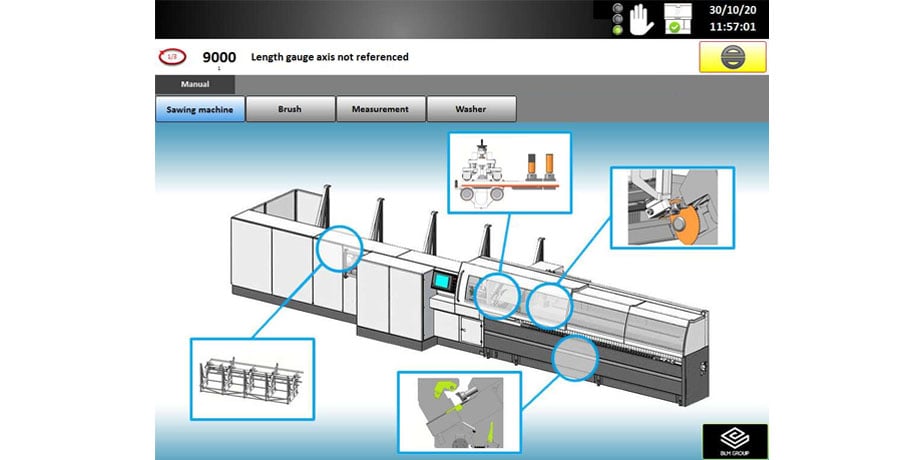

The graphical user interface guides you step-by-step to start production quickly.

Remote operation can be monitored by connecting the system to the network.

.

The graphical user interface lets you easily identify and select the parameters for every element of the machine.

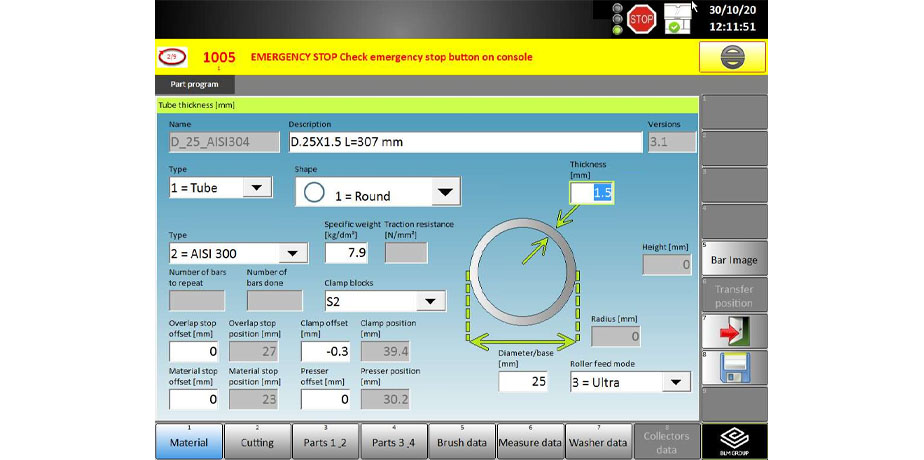

You will find all the parameters needed to change a section on a single, easy-to-read page.

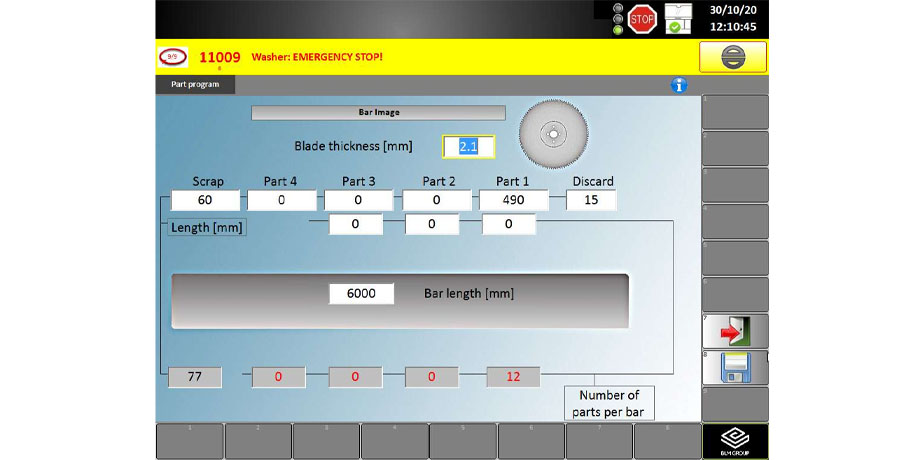

From each bar, you can cut up to four different sizes and discharge to up to four different unloading positions.

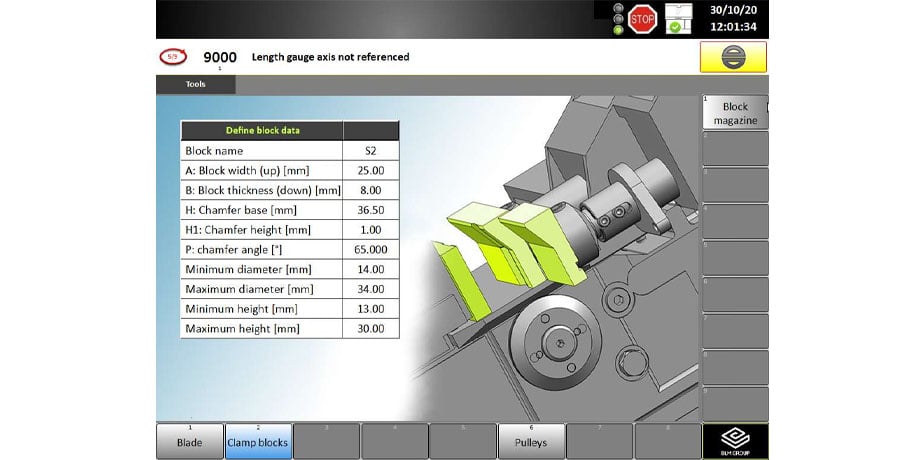

Graphically select the clamping fixtures required for each batch to kick off error-free production.

ProTube:

integrated cutting process

Gain efficiency by organizing multiple machine programs into work orders and sending them to each networked machine through ProTube. ProTube is the remote production scheduling and planning environment. With ProTube, you can create production batches for each machine, specify the required quantities, and transmit the data. The progress of each production can be monitored.

ProTube will calculate the best part nesting on the bar to help you save material. ProTube can also indicate the most appropriate bar length if the material can be sourced to size.