Dimensions, design, geometric requirements and much more; in tube bending being able to achieve a minimum centerline radius can represent a considerable advantage. We are talking about extreme curvatures characterized by a ratio between centerline radius and diameter less than 1, which require significant technological know-how to be achieved.

- Home

- Industries

- Furniture

Furniture and design

New solutions for the design of the future

Unleash your imagination and generate new ideas with BLM GROUP systems. Create new design solutions and try them out now with the integration of tube bending and laser cutting that guarantees you the right part from the start. Reap the benefits of a single source supplier for your production process.

Flexibility at your service

Flexibility at your service

BLM GROUP solutions for furniture

Rely on the experience of BLM GROUP

Quality is simple

For your production, choose easy-to-use systems that guarantee high productivity and quality integrated into a production system that you can control wherever you are.

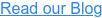

Office chairs

Get the shape you want to structure for a chair, our machines will think about finding simple and cost-effective solutions.

Design solutions that were previously not feasible, or too expensive, are now possible with ease.

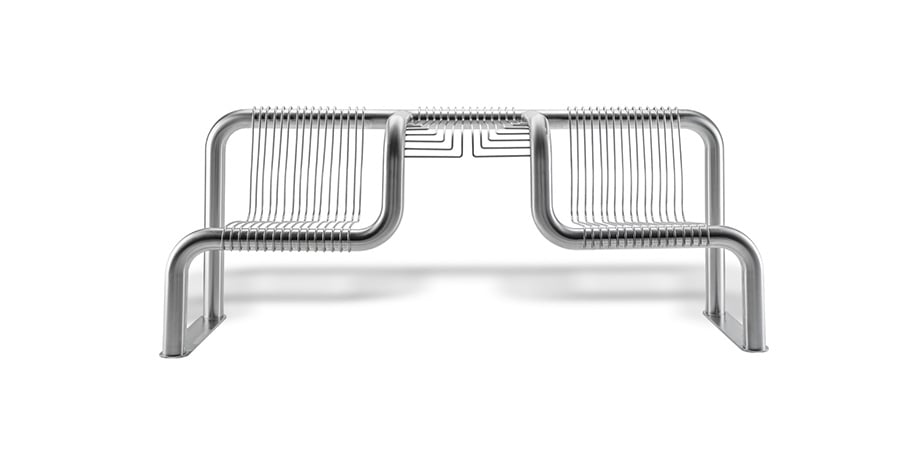

Shelving

POS displays and shelving are easy to assemble and disassemble, robust and attractive. These are just some of the products that can be produced with laser cutting systems for sheet metal, tubes and section bars.

Metal furniture

Combined sheet and tube laser cutting systems, together with bending systems, make it possible to produce structures and covers for cabinets, tables and trolleys for industrial or office applications.

Hospital furniture

Trolleys, cabinets and various types of equipment require machining of curved or laser-cut tubular profiles can be made with an automatic process that guarantees high productivity and great precision in the final product.

Wheelchairs and transport systems for the disabled

Laser and bending systems are widely used for the production of frames and accessories in these productions. The ease of use and production efficiency of BLM GROUP products guarantee effective use in both prototyping and mass production.

Lighting

Lamps, lampposts and lighting systems for indoor and outdoor use are manufactured in an extremely flexible and economical way using tube and sheet laser cutting and tube bending.

Is there a piece you would like to produce with our machines?

Request a feasibility check

Reliability

Reliability

![]()

Remote support

We respond quickly to your needs, to guarantee maximum availability of your system. With our remote assistance services, downtime is minimized and everything else turns into profit.

You can always access the augmented reality of

Active Eye, the smart notifications of the Help button, or the remote diagnostics of TELESER.

Discover our remote support services

![]()

Always close to you

We are always by your side to help you develop new products and optimize your production. Our training services help you develop your skills.

Our maintenance services help you maintain 100% machine availability.

Find your nearest service center

From our blog

Read our articles and discover the most interesting applications for this and other sectors.

From our blog

Read our articles and discover the most interesting applications for this and other sectors.

Having a single supplier for multiple production equipments offers many advantages: a one-stop-shop for assistance, integration and management of production of different process technologies and a partner to build a long-term and trustful relationship with to face future challenges. That’s why Leku-Ona has chosen BLM GROUP.

Furniture

It has achieved a surprising increase in productivity while maintaining the highest standards of quality and safety.

Find out how they do it with E-TURN.

Medical

Hillrom can fully respond to the needs of a highly competitive market through quality and cost control.

Find out how they do it with LT-FIBER.

Furniture

Sedus created the perfect integration between design and production requirements, manufacturing products in which the details make the difference.

Find out how they do it.

Medical

DuPont Medical diversified their production capacity and expanded their market.

Find out how they did it with ELECT and LT5.10.

Fitness

It went from four distinct pieces to just one, thanks to the laser and the fold cut.

Find out how he did it.

Furniture

They make small quantity lots with all the flexibility they need.

Find out how they do it with LT FIBER EVO.

Furniture

They were able to grow and support the rapid changes in the market by choosing technological innovation.

This is why they chose E-TURN and LT8.

High-tech solutions for your sector

BLM GROUP's high-tech solutions

can be found in virtually every industry.

We understand each industry has unique needs and specific requirements. The variety of requests and solutions applied allows you to benefit from experience and ready skills for your needs.