- Home

- Machines

- End Forming

- AST8-VE

- Technical Information

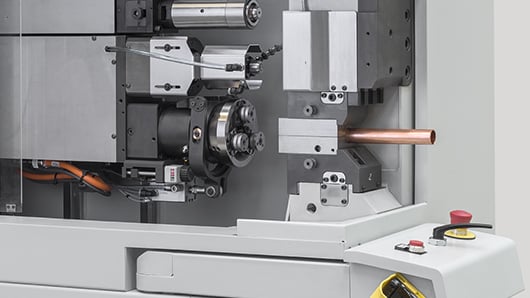

AST8-VE

Vertical end-forming machine with compact layout.

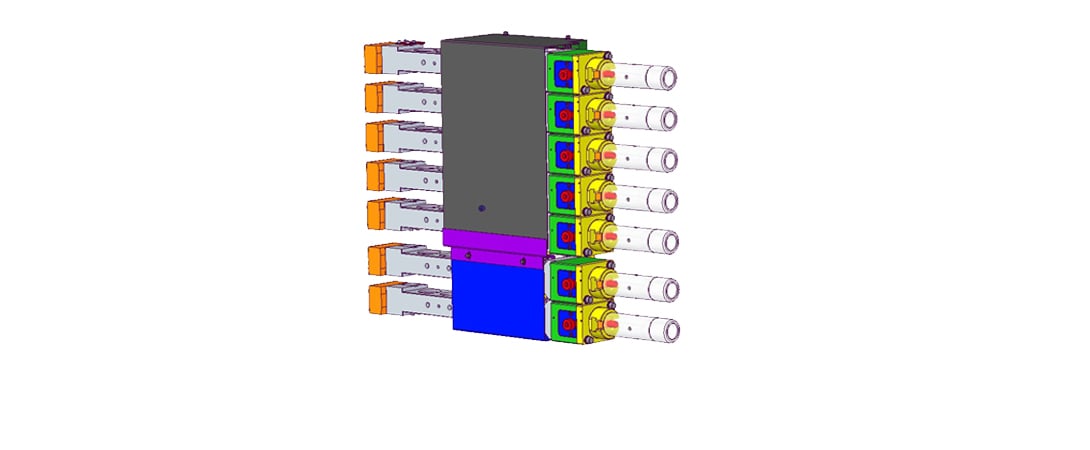

Two configurations for

end-forming ram tools.

Choose the configuration best suited to the job you want to perform.

7 fixed rams

5 fixed rams + 2 rotary tools (one of which can be an orbital cut).

That’s why it simplifies your work!

That’s why it simplifies your work!

Simple in every aspect.

You have the ability to start end-forming and monitor the process from the most comfortable position, thanks to the adjustable control panel always at your side with all the machine systems easily accessible.

This simplifies the programming process and makes maintenance, monitoring and chip removal easier and faster.

Few seconds to change machine tooling.

Perform ram tools changeovers extremely fast! The quick-change system is designed to be simple and allow you to equip each ram tools in a few seconds, eliminating any risk of positioning or clamping errors.

Even inexperienced operators can easily switch to a new production because everything is automatic.

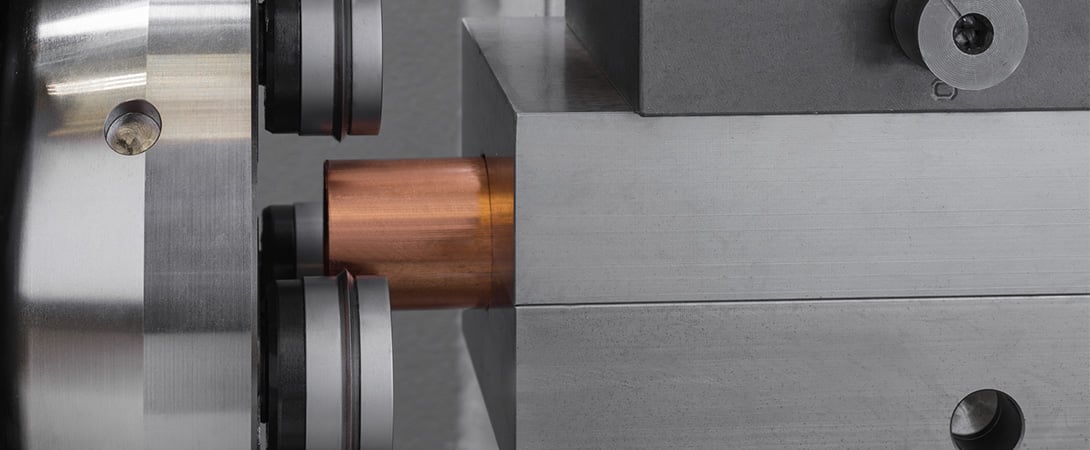

The trim?

Do it in the machine.

You can trim directly on the machine in a simple, fast and clean way.

And you don't even need to manually adjust the cutting position. The CNC does everything!

Optimal position.

No rejects.

The part is positioned simply and safely in the clamp, increasing the repeatability and eliminating defects on the tube by using the pneumatic clamp pre-closing system.

Furthermore, thanks to the vertical configuration of the machine, tube positioning also becomes simpler.

AST8-VE Applications

AST8-VE Applications

Choose the safety

for your job.

AST8-VE is CE certified and designed to the strictest safety standards.

The two-hand activation control prevents the operator from coming into contact with the clamp when processing the part.

The work area is completely closed. The safety-interlocked door is equipped with a large Plexiglas window to control all stages of the work cycle.

The pneumatic clamping device allows the workpiece to be positioned safely at all times.

VGP2D:

learn and start immediately.

Program the work sequence simply and intuitively. Simply select the punch you want to use and VGP2 programming software will set the optimal parameters for you.

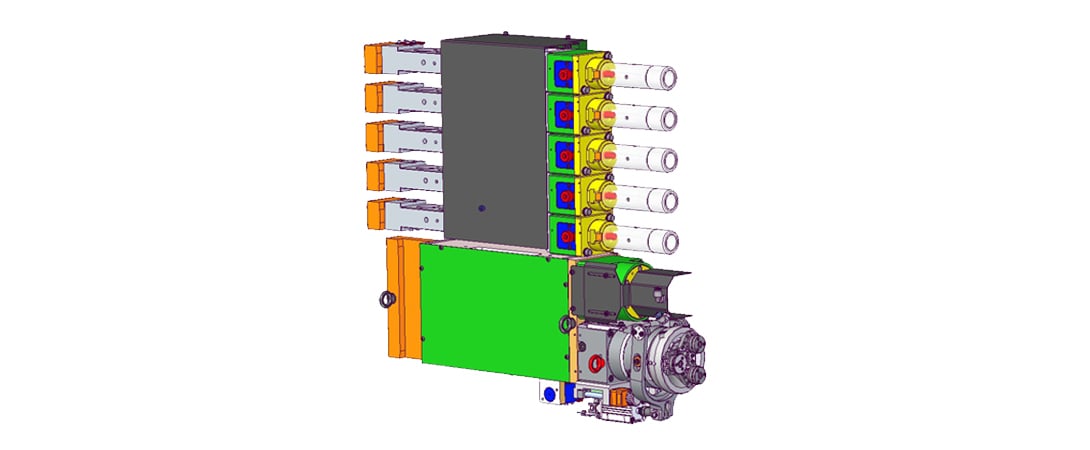

Create your production line.

Create your production line.

Get bent and end-formed part in one efficient work cycle. Eliminate intermediate steps, part reworking on other machines and semi-finished products to be handled and stored. Manage everything from a single point of control.

All our tube end-forming and bending machines are designed to be integrated into complete production processes, allowing you to optimize production.

But integration is more than just that...

AST8-VE technical Information.

Technical characteristics

Maximum workable diameter

40 mm

Maximum working stroke

100 mm

Thrust

80 kN

Clamp closing thrust

125 Kn

Weight of the machine

3.000 kg

Movement

Up to 3 axi