Unlimited possibilities without compromise

Immediate production changeover

LT7 is automatically ready for the next production batch.

At the end of each batch, the loader, spindle, steady rest and intermediate supports automatically adapt to the new section to be cut, without ever interrupting the production cycle.

Boom! You're super efficient!

Flexibility is being free

to choose!

Work independently with the bundle loader.

Pause the workflow to produce small batches, loading one or a few bars on the fly.

Load special and/or open profiles without management problems.

Unload short or long parts, front or back, while scrap is automatically managed.

Integrate robotic loaders or automated storage systems for continuous flow production.

Reliable results in all conditions

Let BLM GROUP Active Tools handle several operations for you.

Accurately cut geometries even on distorted tubes.

Optimized quality and cutting speed even on thick-walled materials.

Change section, material, and thickness without sacrificing cut quality.

The positioning of the internal or external weld seam is always consistent.

In other words, Active Tools are the perfect partners for managing your operations!

The highest productivity at the lowest cost per part

What’s not to love?

BLMelements: the software suite that creates value

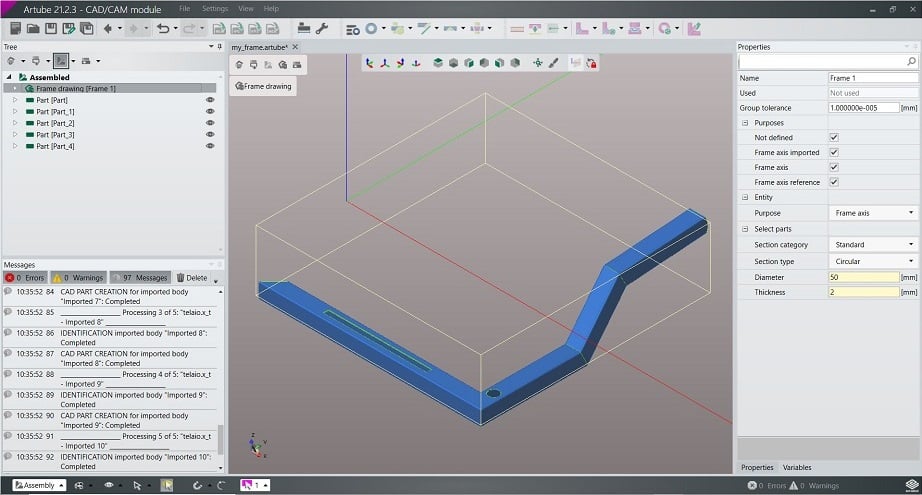

Design of parts and frames in a three-dimensional graphical CAD/CAM environment (ArTube) designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate (PartViewer).

Remote planning and real-time monitoring of work in progress (ProTube).

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.